Industrialized Construction: Should We Mirror Other Industries?

- Luis Antonio Andaluz Burgos

- Sep 15, 2025

- 1 min read

Can construction ever operate like automotive, aerospace, or electronics industries with decades of continuous, automated, standardized production , or is its path inherently different?

The answer may be somewhere in between. There’s much to learn from these sectors’ precision, integration, and efficiency, but construction also carries intrinsic constraints: variable site conditions, regulatory diversity, and the need for high design adaptability.

While advanced industries operate with connected supply chains and high repeatability, construction often works project-by-project, limiting speed, scalability, and cost efficiency. This is not just a challenge, it’s an opportunity. The key question is: where can we act now to accelerate the transition while preserving the flexibility and adaptability required by construction projects?

In recent months, I’ve shared developments aimed at bringing any architectural design closer to modular construction:

-Parametric generators that adapt designs to modular logic without losing intent.

-Automated design-to-fabrication workflows for CNC and prefabrication.

-Industrial process studies to identify where automation and standardization can realistically be applied today.

These are not isolated experiments, they’re building blocks toward bridging the gap.

To frame the discussion, I’ve broken the reflection into two perspectives:

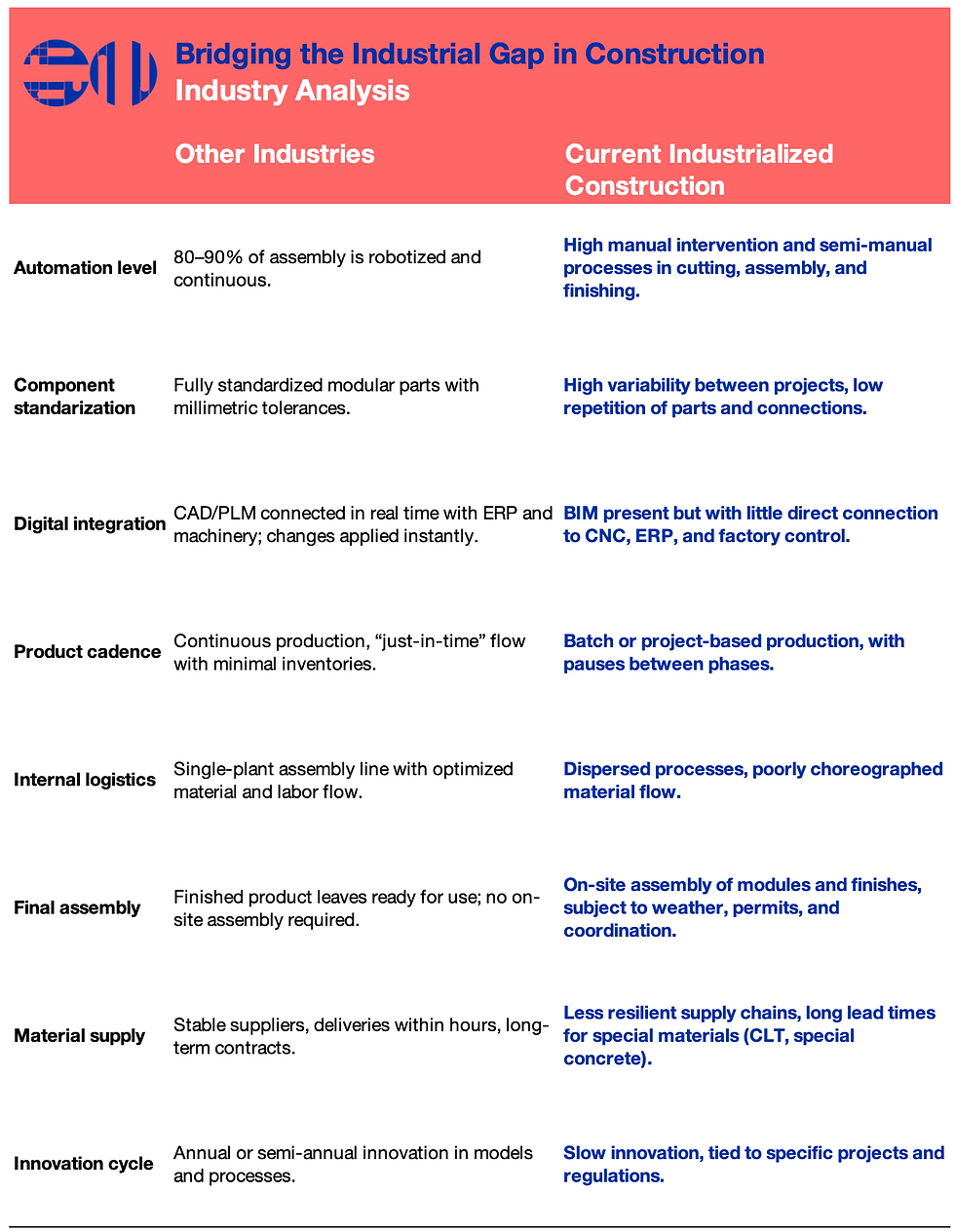

-Industry Analysis: a snapshot of where industrialized construction stands today compared to more advanced industries.

-Value Proposition: staged, realistic actions for short-term impact and long-term transformation.

Construction doesn’t need to be a perfect mirror of other industries, but it can adopt proven principles, adapt them to its operational context, and create its own integrated industrial model. The gap is clear. The opportunities are too.

Comments