top of page

Impact on work

Bridge to the industrialization of construction

Value proposition

Area | Corto plazo | Medio plazo | Largo plazo |

|---|---|---|---|

Component standardization | Development of a catalog of repeatable subassemblies (connections, unions) adaptable to multiple designs. | Validation and optimization of these subsets together with manufacturers. | Validation and optimization of these subsets together with manufacturers. |

Digital integration | Creating a parametric BIM workflow that exports manufacturing-ready data. | Creating a parametric BIM workflow that exports manufacturing-ready data. | Link to ERP and production control for traceability and feedback. |

Final assembly | Definition of pre-assembled components to reduce work on site. | On-site assembly teams trained using standardized methods. | Almost zero on-site assembly thanks to fully pre-integrated modules. |

Innovation cycle | Continuous R&D in parametric design for modular adaptation. | Development of industrialized prototypes for real projects. | Development of industrialized prototypes for real projects. |

Internal logistics | Mapping and optimization of plant layout for pilot lines. | Synchronization of material flows and workstations. | Fully automated internal logistics systems. |

Level of automation | Digital automation of design-to-CNC workflows for repetitive, high-precision tasks. | Digital automation of design-to-CNC workflows for repetitive, high-precision tasks. | Integration with semi-automated assembly tools in the plant. |

Production rate | Pilot production runs for selected components applying JIT (Just-In-Time) principles. | Implementation of continuous flows of small batches | Continuous production of multiple product lines with minimal downtime. |

Supply of materials | Building a network of alternative suppliers for critical materials. | Long-term contracts with key suppliers. | Long-term contracts with key suppliers. |

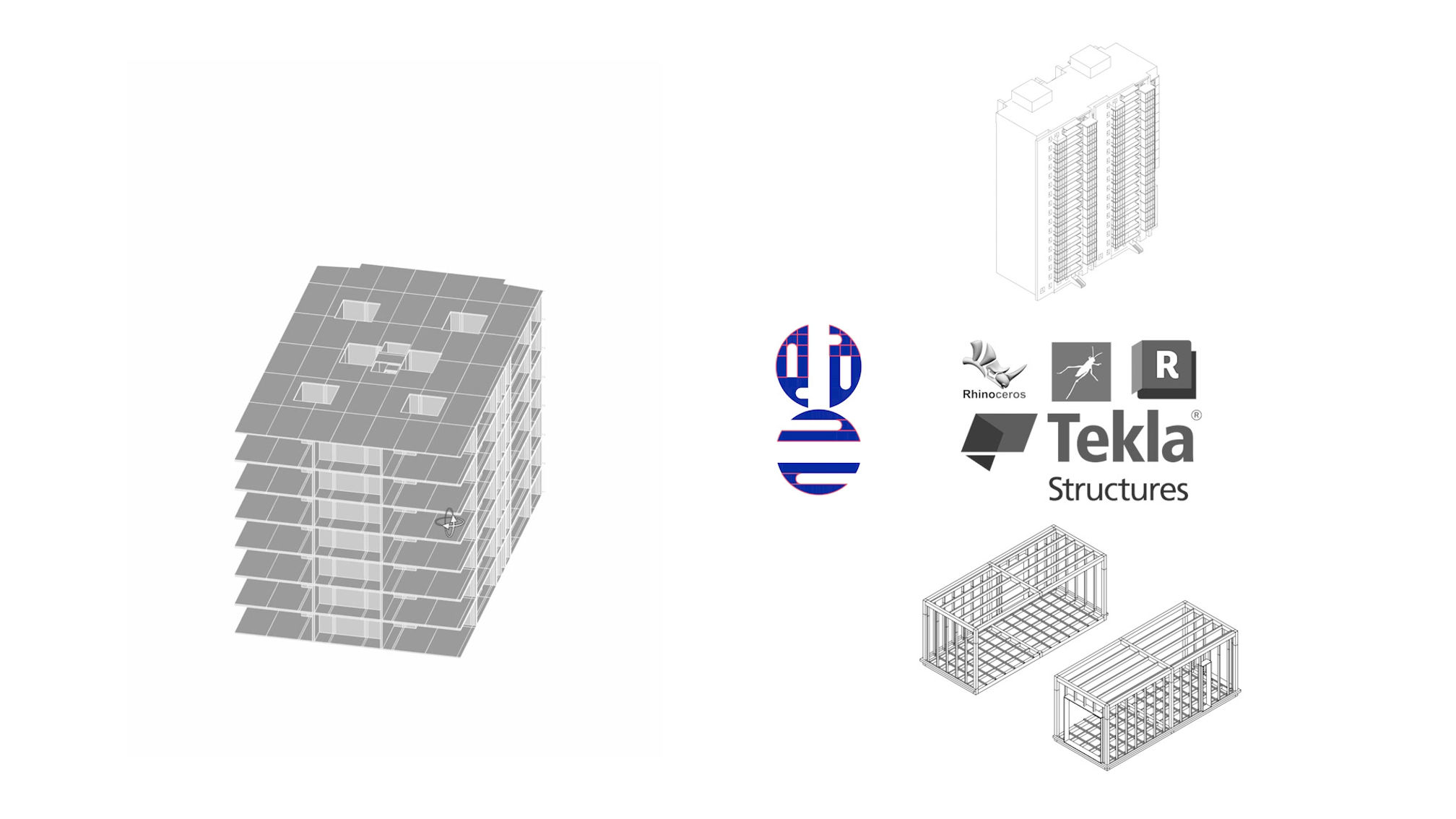

Where technology adapts to architecture

Pillars of innovation in construction

At Per Situ, we believe that every building should be as unique as its designer. We provide vision, innovation, and technological tools that enable architects, developers, and construction companies to optimize projects with greater efficiency, sustainability, and cost control.

Thanks to parameterization, BIM, and industrialized processes, we support the sector in its transformation toward more agile, precise, and responsible construction. Our ambition is clear: to lead the evolution of the industry, promoting new ways of building.

bottom of page